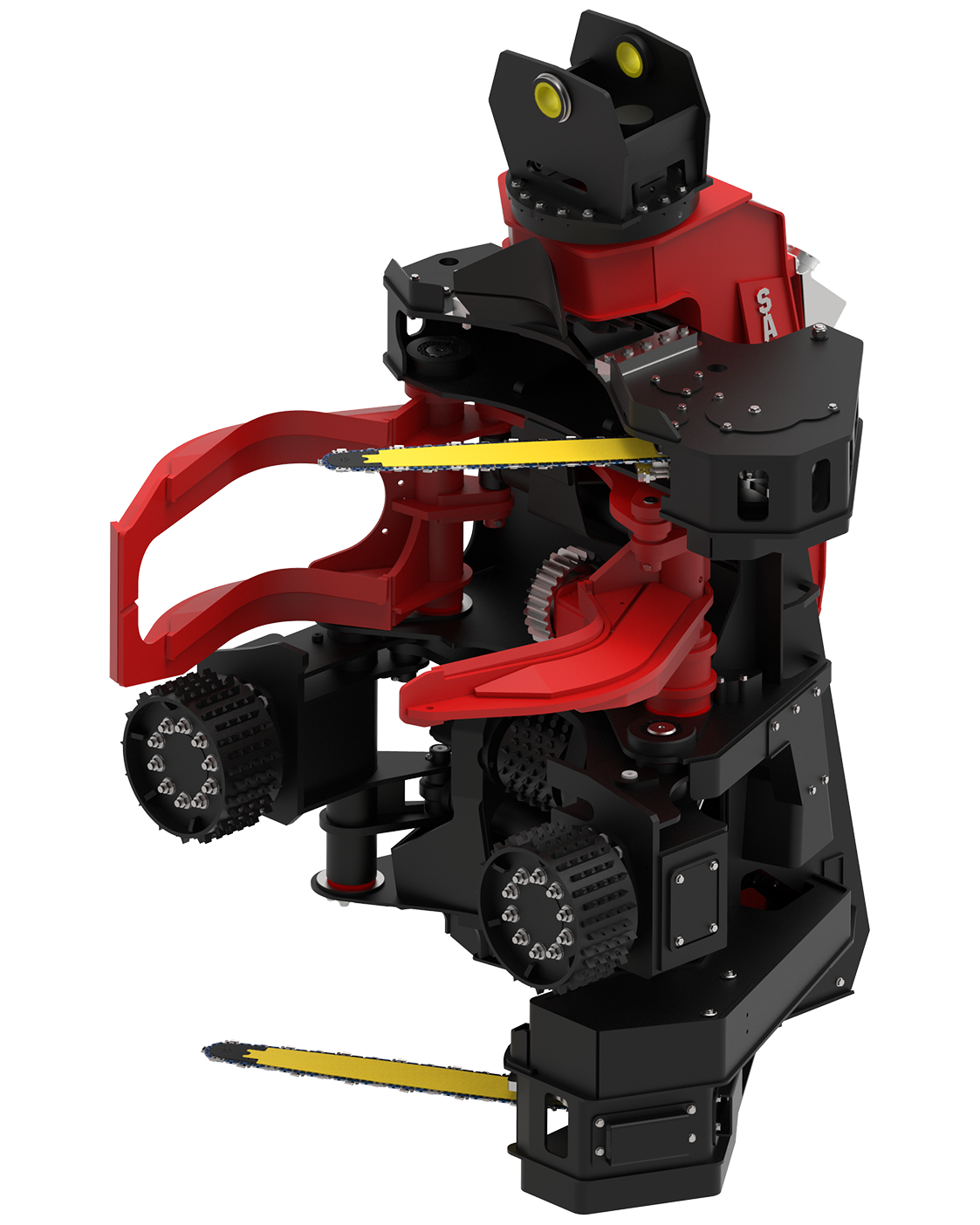

SATCO® 3 SERIES, 3 ROLLER, LARGE CAPACITY PROCESSING HEADS

SAT3L2T/3L2/3L2SC

Key Features:

- Twin tilt cylinders

- 360° continuous rotation

- 8cm (3”) pins for strength & long life

- Long life solenoids

- Rexroth valve rated at 420bar (6100psi) - continuous

- Oil impregnated bushes for less wear

- All pivot pins are retained using the SATCO®"DEAD-LOCK" Pin Retention System, a special clip system adding to the strength of chassis with no extra weight

- Same top saw bar and chain as bottom saw on 3L2T

- Extra ‘dead length’ in cylinders for superior seal life

- Removable covers for easy servicing

- Well protected hydraulic system

- Large 30cm (12”) diameter measuring wheel

- Standard safety chain shot zone lights

- SATCO® Auto chain tensioner

- Saw Limiter

- Harvest Lock

- Find End Shutter - protects Find End when not in use

Further options include:

- Eucalyptus kit

- Alpine or thumbnail softwood rollers

- Colour marking

- Stump Spray

- Bottom Delimb

- Calipers

- Fixed and floating Top Knives

Measuring Options:

- SATCO® Logmaker H3 (Felling Only)

- SATCO® Logmaker H2 (PRIO)

- SATCO® Logmaker H1 (Full Optimising)